Showing 1–16 of 17 results

-

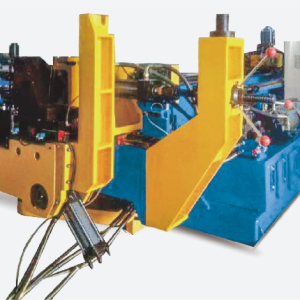

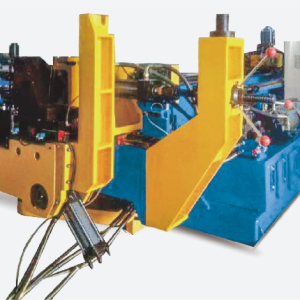

Our Hydraulic Tee Forming Machine also referred to as the Tee Hydroforming Machine, Tee Forming Machine, and Tee Cold Forming Machine, is tailored to handle tee sizes ranging from 1/2 inch to 28 inches, offering versatility and precision across various materials including carbon steel and stainless steel. With user-friendly operation, high production efficiency, exceptional stability, and a long service life, our Hydraulic Tee Forming Machine is the ideal choice for reliable and cost-effective tee-forming solutions.

-

This is a Complex automotive airbag tube automatic tube bending machine that we customized for a large automotive parts supplier. This project uses robot arm to cooperate with our double-mold 4-axis tube bending machine to achieve Complex automotive airbag tube automatic production. The highlight of this Complex automotive airbag tube automatic production project worth mentioning…

-

https://youtu.be/wspBT7DYwYs

-

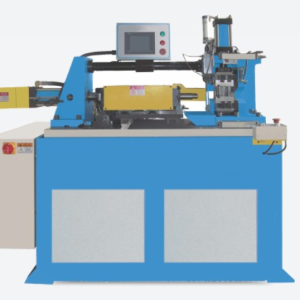

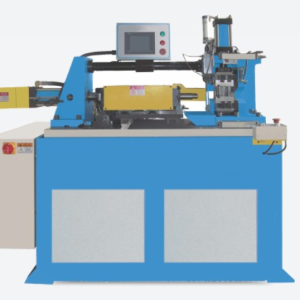

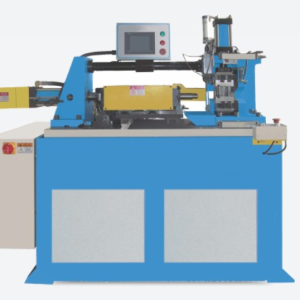

This end-forming machine is applied in processing accessories production of large quantities. The rack of the machine can handle automatic loading, feed, forming, and process.

-

Applicable pipe material: Brass, aluminum, iron pipe, stainless steel tube.

-

Applicable pipe material: Brass, aluminium, iron pipe, stainless steel tube.

Size: 1700x1500x1650mm

-

Applicable pipe material: Brass, aluminum, iron pipe, stainless steel tube.

-

Applicable pipe material: Brass, aluminium, iron pipe, stainless steel tube.

3P size: 1550x1150x1500mm

4P/5P/6P size: 1700x1650x1800mm

-

Applicable pipe material: Brass, aluminium, iron pipe, stainless steel tube.

-

Applicable pipe material: brass, aluminium, iron pipes, stainless steel pipes

Power source selection: pneumatic.

-

Power source selection: pneumatic, hydraulic

Three-axis precision servo control: bending axis, feed axis, the axis of rotation

-

Applicable pipe material: brass, aluminium, iron pipes, stainless steel pipes

Power source selection: hydraulic.

-

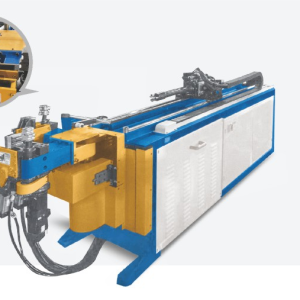

Power source selection: pneumatic, hydraulic Three-axis precision servo control: ent shaft, feed axis, rotation axis, auxiliary push axis, traverse axis, the lift shaft.

Servo axis: 2/3/4/5/6/7

-

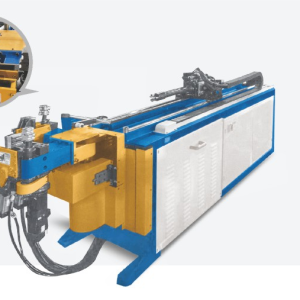

Power source selection: pneumatic, hydraulic Four-axis precision servo control: Bent shaft, feed axis, rotation axis, auxiliary push shaft.

-

Power source selection: pneumatic, hydraulic Three-axis precision servo control: bending axis, feed axis, the axis of rotation.

-